Contact lubrication

Moving moments in every situation

Precise lubrication of conveyor chains during normal operation – with shifting lubrication points – is simple using REBS technology.

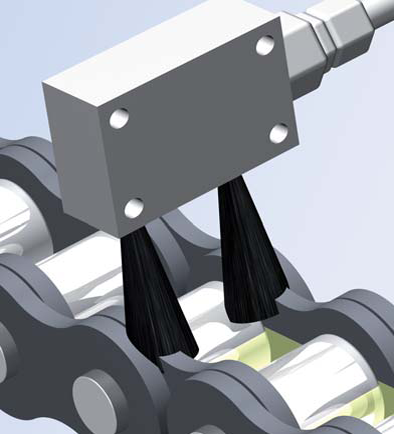

The chain lubrication systems from REBS can be used everywhere where chain pins, chain rollers or load-bearing rollers of conveyor chains have to be dosed with lubricant. It is part of our innovative range of modern, environment-friendly chain lubrication systems, for which REBS is well-known worldwide. It also includes automatic chain lubrication using an oil brush.

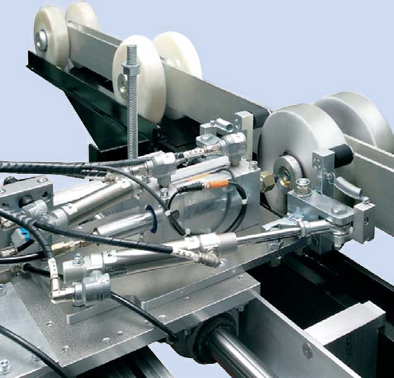

Function of chain lubrication systems for shifting lubrication points.

In the rest position before the lubrication stroke the sledge unit is at the start position. The lubricant cylinder with its centring device is retracted and the sensor counts the chain rollers or bearing pins. The lubrication cycle is activated after a preset number of chain rollers. A work cylinder is positioned and the sledge unit moves with the chain. The second work cylinder, which centres the lubrication cylinder to the chain roller, extends. Now the head of the lubrication cylinder immerses in the lubrication nipple and the predetermined lubricant amount is released. After the lubrication process is complete the cylinders and the sledges go back to their start position.

Advantages

- Optimal lubrication intervals and dosing

- Longer service life

- Reduction of repair costs

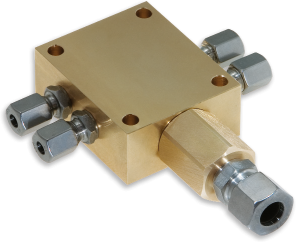

Contact lubricant application

- Slow chain speeds

- Small to medium chains

- Surface treatment (corrosion protection)

Contact EnterLub

- Heavy conveyor chains and transport belts with weight load

- Seal against environmental effects

- High lubricant feed