Contactless lubrication

Very precise and effective - also without contact

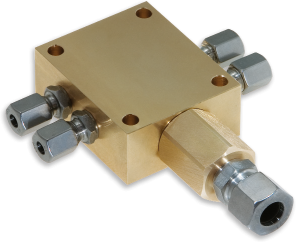

The chain lubrication system generally consists of an oil tank, an electromagnetic piston pump, the spray nozzle and a controller.

The chain oil is fed to the lubrication pump. The lubricant is then transported to the spray nozzle in pulses. To trigger the pump lubricant pulse on the one hand the relevant control unit must report an output signal and on the other hand a proximity switch must signal that the chain pin to be lubricated is in the correct position to the spray nozzle. The sensing of the chain pin can be effected by an optical, inductive or capacitive proximity switch.

Contactless minimal lubricant application:

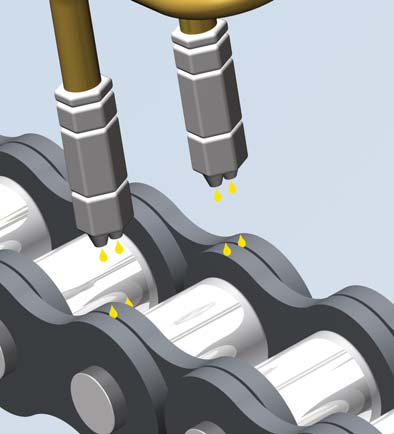

Squirt lubrication

- Almost all chain speeds

- Medium to large chains

- Air-free, very precise application procedure

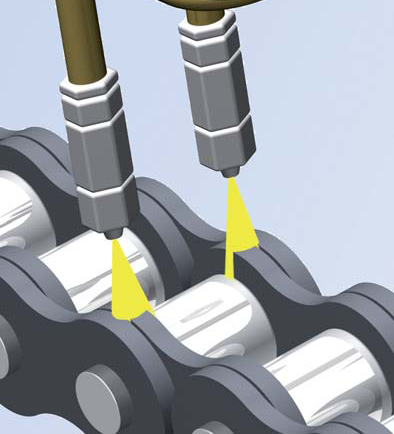

Spray lubrication

- Almost all chain speeds smaller to medium chains

- Also for lubricants with higher viscosity and higher solid matter content

- Large surface treatment (corrosion protection)