Oil-air-lubrication

Quick and hot -

not a problem for us!

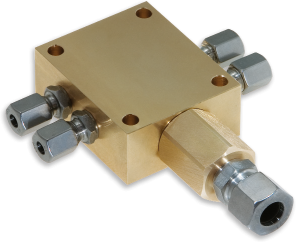

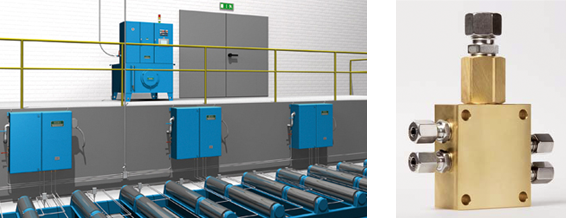

High temperatures, high speeds and loads – the REBS oil-air lubrication with TURBOLUB® distributors is designed for use in extreme manufacturing processes, as well as with small systems from 2.5 litres. The wear-resistance of the distributors and the low lubricant consumption also make these systems economically attractive.

The patented TURBOLUB® oil-air lubrication system is the optimal solution for efficient and reliable lubrication of bearings. Our technology is used for example in continuous casting plants, wire rolling mills and profile iron rolling mills, in cold and hot rolling mills, as well as in roller beds and tunnel kilns. We always have the right system for individual requirements. System parts which are located a great distance from each other are supplied with a lubrication system by a satellite version of the TURBOLUB® system. It can easily be retrofitted with other SAT stations if the lubrication system needs to be expanded.

Advantages of REBS TURBOLUB® technology

- Doubling of bearing and segment service life

- Low bearing temperatures

- Overpressure protects the bearing from dust, scale and water

- Precisely metered lubricant quantities, thus no additional heat through overlubrication

- Consumption of only approx. 5t oil to 100t grease

- No environmental pollution

- Low maintenance costs

- Environment protection through metered oil-air quantities